Companies with deliberate roadmaps will always outperform the ones without them. This article aims to equip you with such a roadmap for your Digital Transformation.

Manufacturers may not realize it until late, but the 4th industrial revolution is right at their doorstep. It is redefining the manufacturing industry with “Digital Manufacturing.”

Digital Manufacturing is manufacturing with technology. It merges physical assets with digital tech— Internet of things, Cloud Computing, and AI — to cut down the wastage and equips you with real-time insights.

Those who are aware crave these capabilities and are clamoring to get them. The race has begun. But the road, however, is full of confusion. Digital Transformation is trickier than what manufacturers thought.

It is about successfully implementing a series of projects connected under a single roof of technology. It cannot happen overnight and never without a proper roadmap. Here’s one to begin your journey.

1. Build Commitment For Digital Transformation

Our recent list of the top challenges in Digital Transformation ranked ‘Stakeholder Resistance’ as the second biggest challenge that a company faces. As it turned out, the collective support of key decision-makers is critical for the success of a transformation.

After all, digitization is a long game. It demands consistent efforts and patience from a company for years. Such patience is not possible without strong commitment among the decision-makers.

Therefore, the journey toward a successful digital transformation begins with the commitments of stakeholders and top-level executives. They must accept the idea of transformation, have a clear vision, and be enthusiastic about it.

Ensuring this will make future stages easy to implement and guard the project against uncertain roadblocks and friction.

2. Examine Your Requirements

Once the commitment is secured, you may feel tempted to begin the project instantly. However, it can certainly bring havoc if you aren’t prepared.

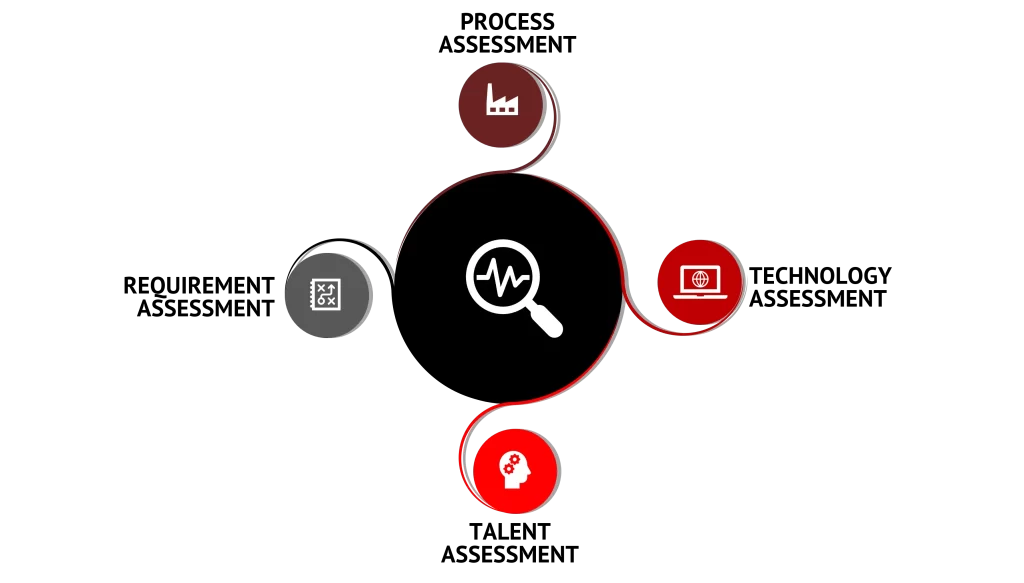

Before initiating the project, the company must know where it stands and how it will execute the project. In other words, you must have:

- A Company Assessment Report

- An Implementation Strategy.

You must acknowledge if the present machines are compatible with the technology that is about to invade the factories, if the talent pool is sufficient, and if the processes are efficient enough.

Getting such insights requires your team to conduct a series of assessments and document their findings. They will help with the feasibility studies and keep the team focused.

3. Define Goals And Strategy

The assessments in the second stage will help you set SMART goals. Setting them will guide you toward specific objectives. Such clarity will help management send clear messages to its employees, partners, and clients.

Since the overall process is turbulent and complex, it is necessary to keep everyone on the same page. Otherwise, unsynced efforts can kill the project very quickly.

To prevent that, leaders must break the project into small sub-projects and decide their completion sequence. The sequence should follow the most-contributing projects to the least-contributing projects.

Note: This stage will serve as the base for most future stages. So it is advised to consult an expert to prepare strategies and project sequences.

4. Create Financial Boundaries

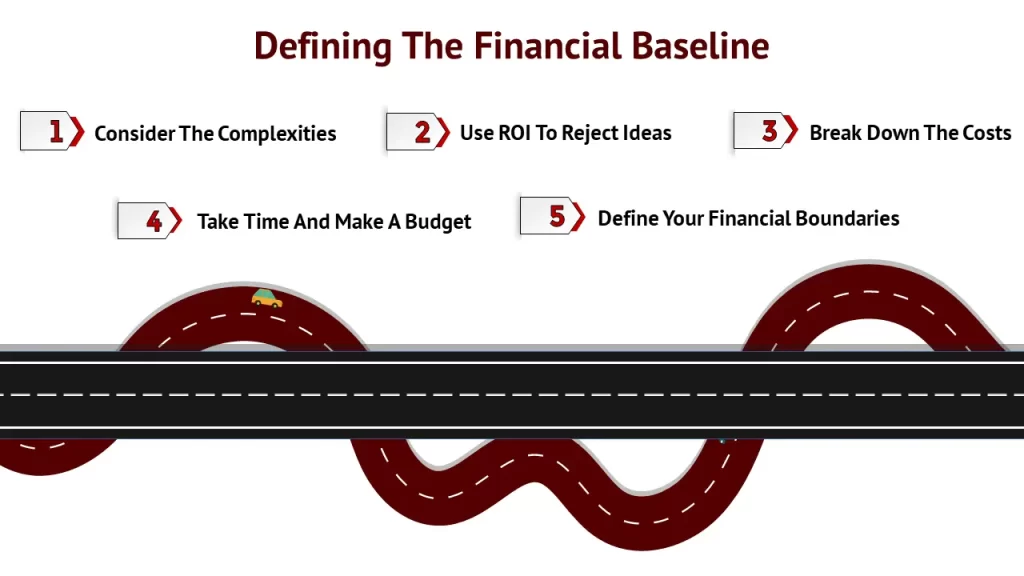

Digital transformation is an ambitious goal. Thus, coming up with ambitious ideas is easy and tempting. However, not all of them will be feasible. Some might be too expensive with low ROIs, while others may be plain unneeded.

To ensure that you are choosing the feasible options:

- Make A Budget.

- Consider the complexities, and break down the costs.

- Define your financial boundaries.

- Consider ROI when selecting or rejecting potential ideas.

- Upon completion, present the budget to authorities and secure a specific investment.

Having a clear budget will not only add clarity to the project but will also make decision-making easier.

5. Choose The Right Partners

As a result of the previous stages, we now have a strong foundation to build on. From here, your focus must shift toward gathering resources and support. Your internal talents won’t be enough to accomplish that, so look outside.

Having never worked on a similar project before, their expertise is limited to their knowledge. Successful transformation demands experience-based expertise to cope with surprises and uncertainties along the way.

Experience-based expertise is the key ingredient in all project phases, be it planning, implementing, or transitioning. Therefore, partner with experts who have already traveled the road.

Example: Elysian Corptech assists manufacturing companies throughout their Digital Transformation. It helps them build successful strategies. It supplies them with the tools they need for integrations and even manages their complex projects.

6. Build An Outstanding Team

After deciding your goals, financial boundaries, and the right partners, it’s time to build an outstanding team. A high-caliber team will make the project possible and propel it towards success.

Appointing such a team may include picking from the available talent pool, sourcing outside talents, or choosing a hybrid option. Whichever option you choose, give special attention to the recruiting and hiring process.

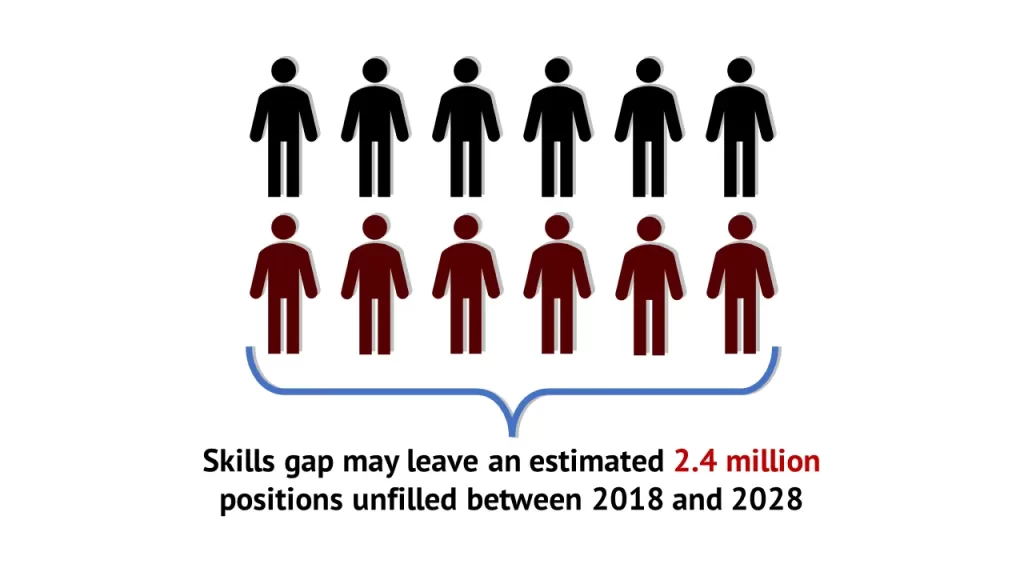

As the market for digital talent is more competitive than ever, finding and retaining talent has become a big challenge. As per a study conducted by Deloitte, the skills gap may leave an estimated 2.4 million positions unfilled between 2018 and 2028.

7. Start With Small-scale Projects

Companies often make the mistake of jumping directly into big projects. Starting with the behemoths is never a good idea; you must walk before you run.

Start with light projects. Choose those that offer the highest return on time and resources invested.

- Create initiative measurement criteria and KPIs for tracking.

- Prioritize goal-based dynamism.

- Inspire your teams to take forward-looking initiatives.

- And in motion, Instill agile methodologies into the workflow.

Following this process, jump from one sub-project to another, filling the large picture of organization-wide digitization.

Note: The company must have a strategic sequence of sub-projects ready (refer to stage 2). The goal is to transform the entire company without interrupting existing production.

8. Nurture A Digital Culture

Humans resist change. Shifting from traditional manufacturing to digital manufacturing will cause your people to resist. They will find it difficult to drop their old methods and adapt to the updated ones.

It is, therefore, the management’s duty to familiarize them with digital tools and workflows right from the beginning. It must expose employees to digital tools and ensure they know what they can do with them.

Before the transition ends, employees must feel comfortable working in a digital environment. A digital-friendly culture from the beginning will smooth the transition and enhance efficiency.

9. Build Capabilities

Many manufacturing workers lack the skills and expertise to work in tech-savvy environments. Therefore, a company must emphasize acquiring new talent and retraining the older ones from the beginning.

The goal must be to balance the requirement-availability equation for talents and keep it balanced.

10. Transition To A New Operating Model

Our roadmap’s last step is moving to the upgraded operating model. This stage will be the climax point of the Digital Transformation where all the sub-projects align.

It will also be the most difficult stage since it will completely change how the company operates. Employees will resist the changes in norms and workflows. Thus, effective change management must be the top priority.

The efforts in nurturing the digital culture will pay off here — the better the nurturing, the lower the resistance. And the lower the resistance, the smoother the transition will be.

Conclusion

In the process of Digital Transformation, manufacturers will face challenges every day. For some projects, the ROI may be inaccessible. In others, the cyber security team may fall behind schedule; or the stakeholders may start to resist the project.

However complex the problems may be, companies with effective frameworks will always be more agile and responsive than the ones without them.

Check out our blogs for more insightful articles.